At face value, Ford’s wet timing belt appeared to be a smart piece of modern engineering. Quieter running, compact design, and improved efficiency all sounded like wins for drivers.

In practice, the wet belt has become one of the most criticised engine designs in recent years, responsible for widespread mechanical failures and repair bills that often exceed the value of the car. For many owners, it is a problem they do not even know exists until it is too late.

What Is a Wet Belt and Why Ford Used It

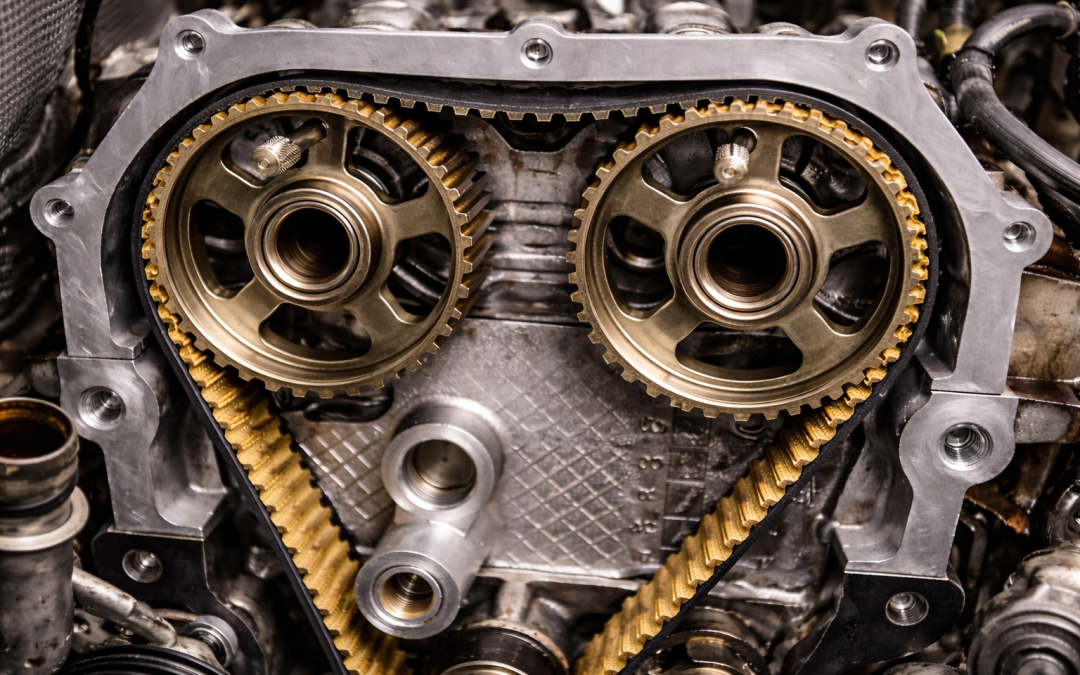

Traditionally, engines rely on either a dry rubber timing belt or a metal timing chain. Ford took a different approach by fitting a rubber belt that runs inside the engine, permanently immersed in engine oil.

The theory was simple. Oil would lubricate the belt, reduce noise, improve efficiency, and allow tighter engine packaging. It also reduced manufacturing costs compared to chain driven systems.

Unfortunately, real world use has shown that this design introduces a serious weakness.

Why Oil Choice Is Critical

The single biggest factor in wet belt failure is engine oil. These engines rely on a very specific Ford approved oil formulation to prevent damage to the belt material.

This is not a general recommendation. It is essential to the survival of the belt.

Many vehicles have been serviced using incorrect oil, often unknowingly. Even when oil viscosity appears correct, the additive package may not be compatible with the wet belt.

How incorrect oil destroys the belt

Most engine oils are designed for metal components. Their detergents and additives are not formulated to protect rubber belts submerged in oil.

When incompatible oil is used, the belt material begins to soften and swell. Over time it starts to break down and shed rubber particles into the oil system. The belt does not simply wear out. It slowly dissolves.

From Minor Degradation to Total Engine Failure

Once the belt begins to degrade, the damage accelerates rapidly.

Stage one: hidden belt breakdown

Rubber particles are released into the engine oil. At this point there are usually no warning signs.

Stage two: oil system contamination

Debris circulates through the engine and collects in the oil pump strainer. This fine mesh filter gradually becomes blocked.

Stage three: oil starvation

As the strainer clogs, oil flow and pressure drop. Components that rely on constant lubrication are starved of oil.

Stage four: turbo damage

The turbocharger is often the first major component to fail due to its extreme operating conditions. Lack of lubrication destroys bearings and seals.

Stage five: catastrophic engine damage

With oil pressure compromised, internal engine components suffer rapid wear. Bearing failure, seized components and complete engine failure can follow.

By the time warning lights appear, the engine may already be beyond economical repair.

Confusing Service Intervals

Ford’s guidance on wet belt replacement has changed over time, creating confusion for owners.

Early service intervals suggested very long replacement periods. These were later reduced for some engines, but many specialists believe even the revised figures are optimistic.

In real world conditions, heavily degraded belts are often found far earlier, especially where oil history is incomplete or incorrect oil has been used at any point.

Warning Signs That Often Come Too Late

Wet belt failure rarely gives clear early warnings, but possible symptoms include:

-

Unusual rattling noises, especially on cold starts

-

Engine warning lights related to timing or oil pressure

-

Rough running or misfires

-

Noticeable loss of power

Low oil pressure warnings usually indicate advanced damage rather than an early problem.

The Financial Impact

Replacing a wet timing belt is a major job requiring extensive engine disassembly. Labour costs are high, even when no additional damage has occurred.

If belt degradation has already affected the oil system, turbocharger or engine internals, repair costs can escalate rapidly. In many cases, owners are faced with bills that make repair uneconomical.

How Owners Can Reduce Risk

If you own a Ford fitted with a wet belt engine, prevention is critical.

Always insist on Ford specific oil at every service.

Keep detailed service records showing correct oil usage.

Consider replacing the belt earlier than official guidance suggests.

Reduce oil change intervals to keep oil clean and minimise contamination.

Investigate any unusual noises or warning lights immediately.

Industry Criticism and Legal Action

The wet belt issue has drawn significant criticism from independent specialists and consumer groups. Legal action has been taken in multiple countries, and extended warranties have been offered for some vehicles.

Despite this, there has been no widespread recall and no full acknowledgement of a fundamental design flaw.

Final Thoughts

The Ford wet belt is a reminder that innovation does not always lead to long term reliability. What was intended as a cost saving and efficiency driven solution has instead become a serious ownership risk.

For current owners, awareness and preventative maintenance are essential. For potential buyers, understanding the wet belt issue could prevent a costly mistake.

In this case, correct servicing is not just about good maintenance. It can be the difference between a reliable engine and a sudden, catastrophic failure that ends a vehicle’s life without warning.